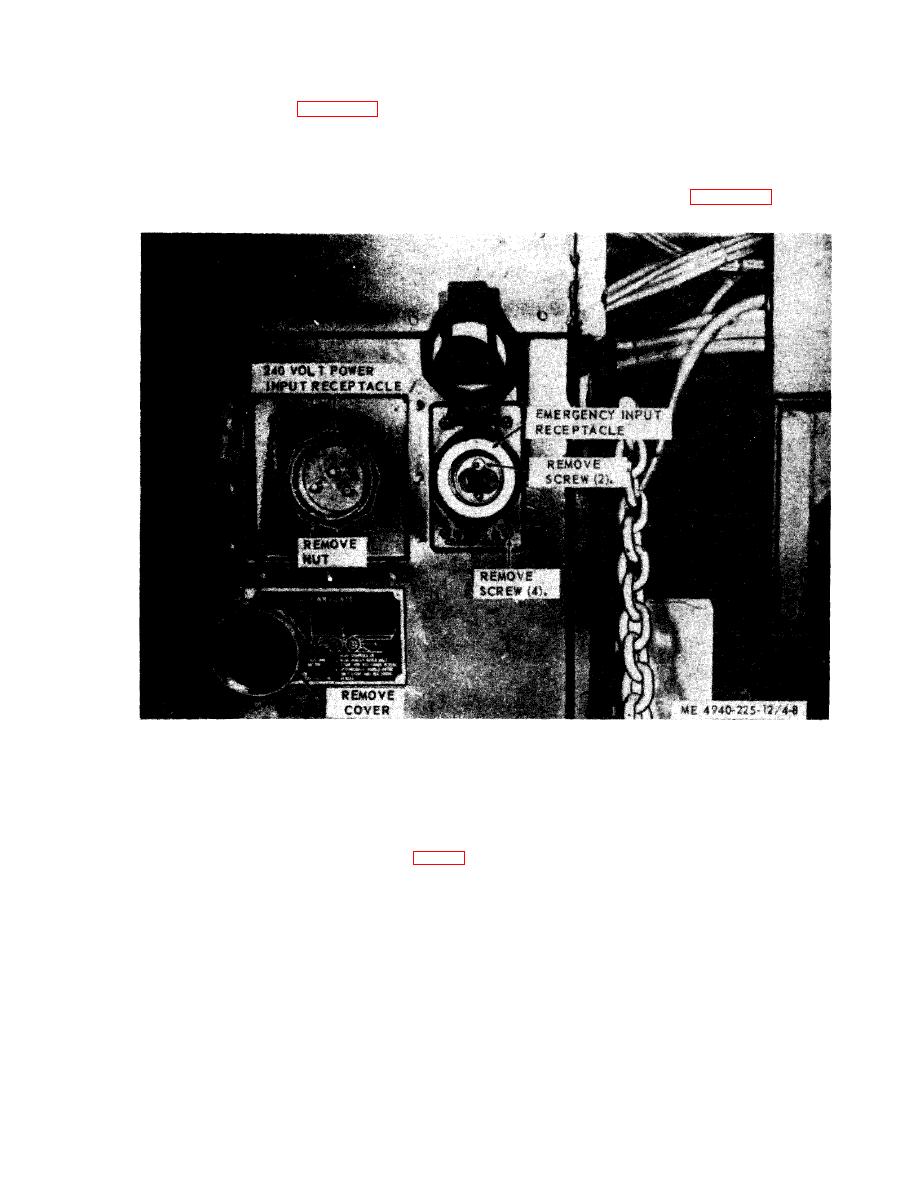

4-18. Emergency Power Receptacle

(3) Replace defective or missing hardware and

parts as necessary and be sure all electrical con-

a. Removal. Remove the emergency power

nections are clean and secure.

receptacle as illustrated in figure 4-8.

(4) Inspect jumper cable for damage and

b. Cleaning and Inspection.

broken or cracked insulation. Replace a defective

(1) Clean metal p-arts with cleaning solvent

cable that cannot be repaired.

and dry thoroughly.

c. Installation. Install the emergency power

(2) Inspect for defective or missing hardware

receptacle as illustrated in figure 4-8.

and loose electrical connections.

Emergency and external power receptacle. removal and

installation.

the emergency receptacle. Then remove the ex-

ternal power receptacle and electrical leads as an

a. Removal.

assembly.

(1) Remove the large nut that retains the

receptacle in the side panel, then remove the

b. Cleaning and Inspection.

(1) Clean parts with a cloth dampened in

receptacle out through rear of the side panel (fig. 4-

clean in g solvent.

8).

(2) Inspect for defective or missing hardware

(2) To replace a defective receptacle, unsolder

and loose electrical connections. Replace loose or

the electrical leads and resolder them to the new

missing parts and be sure electrical connections are

receptacle.

secure.

(3) To remove the receptacle for other pur-

(3) Inspect wiring for breaks or damaged

poses, unscrew the knurled knobs that retain the

insulation and repair or replace wiring as necessary.

dynamotor hinged control panel in closed position

c. Installation. Install the external power

and open control panel. Remove the three electrical

receptacle in reverse order of paragraph a above.

leads marked with circuit No. 220, 221, and 222,

from the back of terminals Ll, L2, and L3, below