turn differential screw at edge counterclockwise.

When adjusting this screw, do not turn it farther

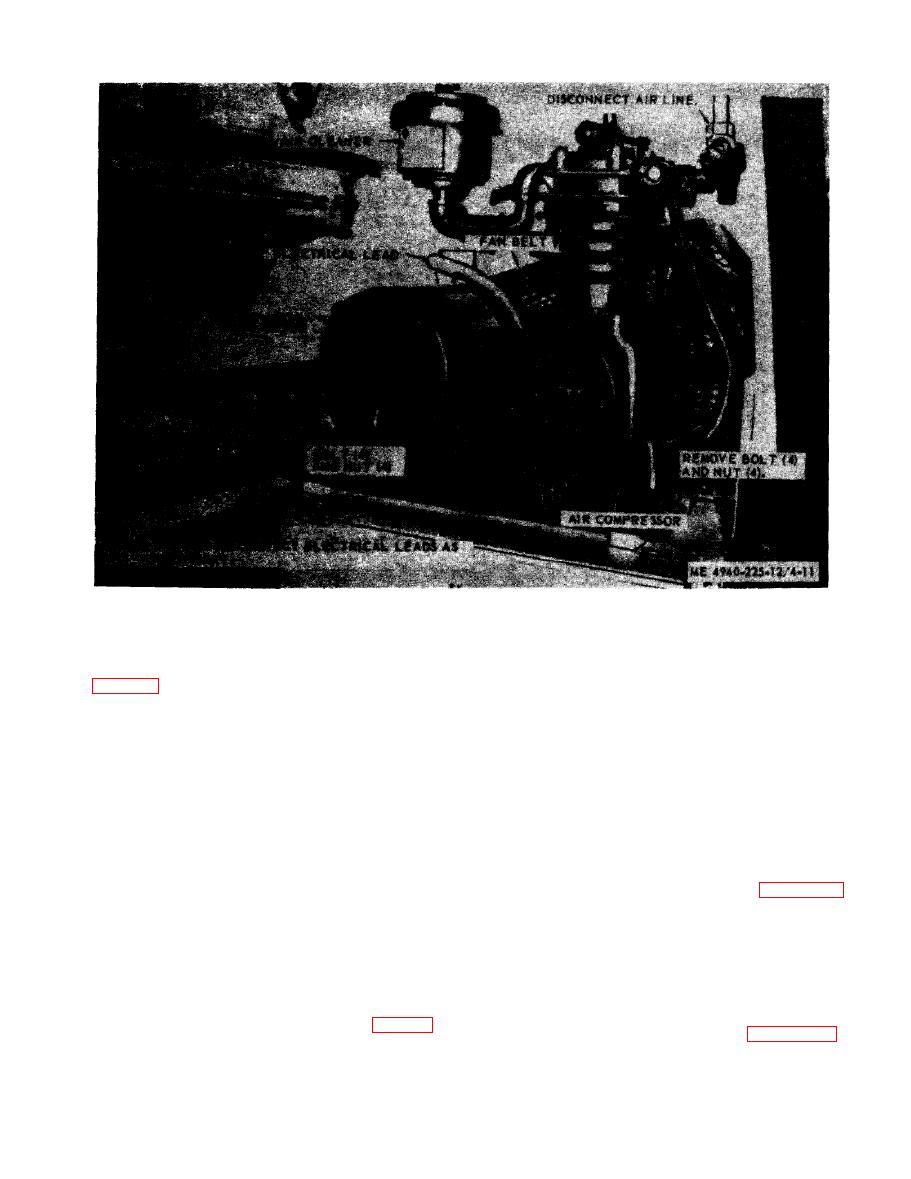

d. Removal. Tag and disconnect electrical lead

than it will turn easily.

c. To increase DIFFERENTIAL and maintain

remove drive motor assembly.

same CUT-OUT pressure, turn differential screw at

b. Installation. Install the drive motor on the

edge clockwise and at the same time turn center

compressor base and secure with bolt (4) and nut

screw counterclockwise.

(4).

CAUTION

c. Belt Adjustment. Loosen the drive motor

If differential is increased only by

holdown bolts (4) and slide the motor on the base

turning screw at edge clockwise, the

to give the belt a 1-/2 inch deflection between pulleys.

cut-in pressure changes only slightly

Tighten the motor holddown bolts (4).

and the cut-out pressure rises.

4-31. Drive Motor Sheeve

a. Removal. Loosen setscrew and remove sheeve.

b. Installation.Place sheeve on drive motor shaft

12 and remove and disassemble the unloader.

and tighten setscrew finger-tight.

b. Cleaning and Inspection.

c. Alignment. Place a straight edge on the air

(1) Clean parts with cleaning solvent and dry

compressor pulley and align the drive motor sheeve

thoroughly.

to the straight edge and tighten the setscrew.

(2) Inspect for rust or corrosion that could

cause improper fit and function of the unloader.

a. To raise CUT-IN and CUT-OUT pressure,

c. Reassembly and Installation. Reassemble and

turn pressure adjusting screw clockwise (fig. 2-11).

install the unloader as illustrated in figure 4-12.

b. To lower DIFFERENTIAL (namely, the

difference between cut-in and cut-out pressure),