TM 55-4920-402-13&P

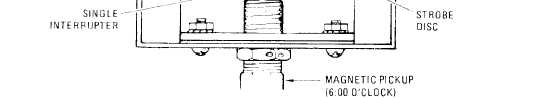

Figure 3-3. Tester Interrupter Placement

stopped under 60 HZ fluorescent lighting,

adjust 900 RPM adjust (fig. 3-2) until these-

cond ring of black and white segments ap-

pear to be stopped.

(3) Connect Balancer Power Cable to the Tester

and ensure Tester Power Cable is still con-

nected to +28 vdc power source,

(4) Set Balancer controls as follows:

(a) INTERRUPTER LOGIC to DOUBLE.

(d)

(b) MAGNETIC PICKUP to COMMON.

(C) RPM RANGE to X10.

1.

(d) RPM TUNE to 180.

(e) FUNCTION to CHANNEL A.

(5) Adjust Tester as follows:

Adjustment with 50 Hz power source for

the fluorescent lights is the same as for 60

Hz with the following exceptions:

The tester strobe disc speed is Calibrated

using the two inner rings of black and

white segments. The third ring from the

outside will appear stopped when the

strobe disc is turning 1714 rpm. The inner

ring (fourth from the outside) will appear

stopped when the strobe disc is turning 923

rpm.

(a)

(b)

(c)

Set MOTOR switch to ON.

Set CAM RATE (RPM) switch to 1800 and

observe that the black and white outer ring

2.

of segments on the strobe disc appear to be

stopped when illuminated by 60 Hz fluores-

cent room lights. If yhe segments are not

stopped under 60 Hz fluorescent lighting,

3.

adjust 1800 RPM adjust (fig. 3-2) until the

outer ring of black and white segments

appear to be stopped.

Set Tester CAM RATE (RPM) and Balancer

The rpm settings of the Balancer and Stro-

bex shall read 1714 and 923 instead of 1800

and 900 respectively.

Ensure rpm readings are still within ±2%,

and IFS meter readings are still within

±10%. The Balancer IPS meter reading

shall be 0.75 @ 1714 rpm and 0.47 @923

rpm.

RPM Tune to 900. RPM RANGE to Xl.

(6) Set Tester rotor for double interrupter with

Observe that the second ring of black and

all six screws in place (fig. 3-3).

white segments on the strobe disc appear to

be stopped when illuminated by 60 Hz

fluorescent room lights. If segments are not

(7) Set Tester CAM RATE (RPM) and Balancer

RPM Tune to 1800 RPM, RPM RANGE to

X10.

3-4

Change 4