TM 55-4920-402-13&P

Strobex RPM control, the blades may be spread for easy

resolution. When applied to the two blade rotor system

(Bell) where two interrupters are installed on the swash-

plate, position B is used for greater light output. The

oscillator is set to flash at a rate slightly slower than

bade rate (in accordance with the formula on the back

of the Strobex, RPM=blade rate X 0.4). Then, the interrup-

ter commands the Strobex before the oscillator, and it

operates as if there were no oscillator. In this case, the

targets cannot be spread. The oscillator may be set to

double the blade rate, in which case the Tip Targets will

be seen at twice as many positions around the rotor disc.

For instance, the targets of a two-blade rotor are typically

seen at 12:00 and 6:00 o’clock (as determined by location

of Interrupters). If the oscillator is set to double the blade

rate, the targets will also be seen at 3:00 and 9:00 o’clock.

(3) Mode C Mode C is a free-running oscillator

and is used as a tachometer for speed (RPM) measuring.

All external signals are disconnected and the Strobex

flashes only in response to its internal oscillator. Flash

rate is adjustable from 100 to 1,000 RPM (flashes-per-

minute).

(4) Mode D. Mode D is also a free-running oscil-

lator and is used for tail rotor tracking and speed measuring.

Since there is no Magnetic Pickup mounted on the tail ro-

tor, the flash rate of the free-running oscillator is adjusted

to double or four times the rotor rate (for a two-blade tail

rotor), so the single Tip Target appears as a stopped image

of two or four. Then, by viewing the rotor disc edge-on

from the cabin door, reflective Tip Targets can be seen

superimposed for a judgement of track. Flash rate is from

1,000 to 10,000 RPM.

(5) Mode E. Mode E is a locking oscillator like

Mode B, but operates at higher rates and is used for view-

ing the track of airplane propellers. It requires a Magnetic

Pickup input pulse.

4-9. Tester.

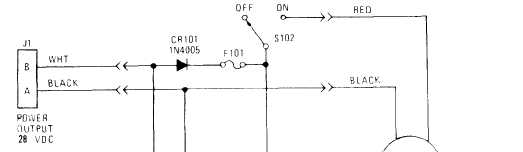

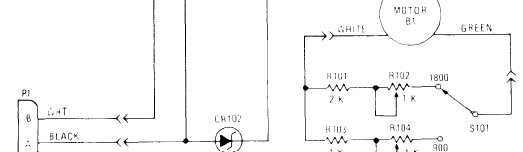

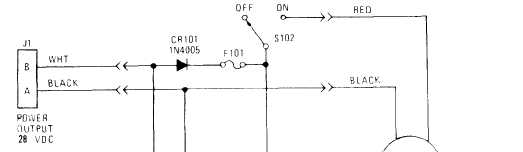

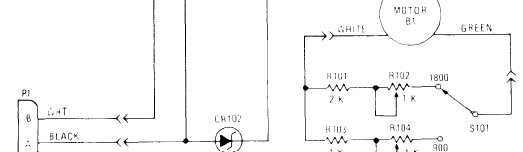

a. The circuitry in the Tester (fig. 4-4) includes a 2-

ampere fuse (F101) and a 36-volt zener diode (CR102).

These components protect motor drive circuit (B1) in the

event the unit is accidentally connected to an improper

power outlet.

b. CR101 is a polarity project diode which prevents

reverse dc voltage from being applied to B1. If reverse

polarity is applied, no damage will result, but the unit

will not operate until polarity is corrected.

c. Switch S101 selects either R102 or R104 to syn-

chronize B1 motor speed.

d. Switch S102 applies 28 vdc power to the B1 motor

drive circuits.

Section III.

TROUBLE ANALYSIS AND REPAIR

4-10. Trouble Analysis. This section contains instructions

trouble to the Balancer, Strobex, airframe mounted compo-

and procedures for troubleshooting and repair of the

nents, or interface cabling. Normally, this will have been

VIBREX. Use of the Tester is the basis for isolation of a

Figure 4-4. Tester Schematic Diagram

Change 4

4-7