TM 9-243

USING THE PORTABLE ELECTRIC DRILL - CONTINUED

TWIST DRILLS

Twist drills are the most common tools used in drilling

metal and are made in many different sizes and lengths.

These drills are made of carbon steel or high speed alloy

steel. Carbon steel drills are used for general drilling

while the alloy steel drills are used for drilling hard

metals such as stainless steel.

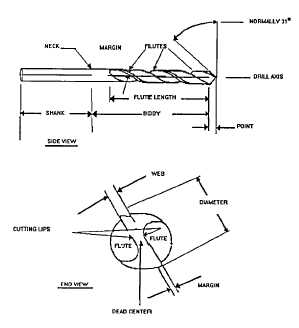

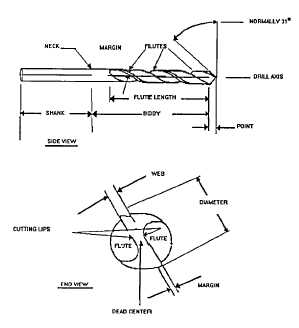

DRILL TERMINOLOGY

A twist drill has three main parts: point, body and shank.

1.

The point of the drill is the cone shaped end

(normally 31 degrees) which does the actual cutting.

2.

The body is the center section of the drill between

the point and shank. The cut-out portions of the

body are called flutes. The flutes serve a definite

function In that they cause the metal chip to curl

tightly within itself occupying a minimum amount of

flow easily down to the cutting edge.

3.

The shank of the drill is the end that fits into the drill

chuck.

The actual cutting is done by the cutting lips or edges

which are formed by the intersection of the flutes and the

cone-shaped point. The dead center of the drill is the

edge at he extreme tip of the point. The dead center

should always be in the exact center of the drill axis.

When drills are reground, it is possible to have the dead

center point off center, resulting in one cutting lip doing

most of the cutting and placing excessive strain on the

drill. The narrow strip at the edge of each blade is called

the margin. This strip, which extends the entire length of

the flutes, is part of a cylinder interrupted by the flutes.

The actual drill diameter is measured from margin to

margin.

DRILL SIZES

The twist drills available at the sites are designated in

two different ways:

1.

Fractional sizes - These drills come in sizes from

1/32 inch to 1/2 inch. The difference between one

drill size and the next larger is always 1/64 inch.

2.

Numbered sizes - These drill sizes vary from #1

(0.2280 inches) to =80 (0.0135 inches). The

smallest numbered size drill stocked at the sites is

=60 (0.0400 inches).

If the size number, which is etched on the drill shank has

worn off, the drill size can be obtained by using a

micrometer. Measure the drill from the margin to margin

on the drill body near the shank end. This shank

diameter is usually a few ten thousandths of an inch

smaller than the point diameter.

USING THE DRILL

Prior to performing the job the proper size drill bit and

drill motor must be selected. Tables 3 and 4 in the

Appendix list the various drill bits available. There are

two drill motors available at the site:

1. A high-speed motor, 1/4 inch capacity drill motor is

used for general drilling of light metals

2. A 1/2 inch capacity used for drilling large holes. The

motor of the 1/2 inch capacity drill is geared down to

prevent overheating the drill bit.

The object to be drilled should be held in a vise when

possible. Never attempt to hold the work with your

hands. The drill may catch or jam and start the stock

spinning. When this occurs the stock may fly loose and

injure personnel In the immediate area. When

52-5.0 Change 3