TM 9-243

USING THE PORTABLE ELECTRIC DRILL – CONTINUED

drilling thin sheet stock, back up the stock with a piece of

wood to prevent the stock from being bent out of shape.

When the location of the desired hole is selected, it

should be center punched. This will aid the drill in

starting to cut and will prevent it from wandering. Turn

the drill chuck a few times by hand before turning on the

power to insure that the drill bit is properly installed.

Keep the drill cutting at all times while in contact with the

metal. A steady and uniform pressure should be applied

at all times to insure continuous cutting. The drill will

become excessively hot if permitted to turn on the metal

without cutting When the drill point is about ready to

break through the metal, ease up on the pressure. This

point in noted by the difference in pressure and cutting

feel. Don't permit the drill to project through the hole.

When the hole is complete, remove the drill immediately

by pulling it back as it continues to turn in a clockwise

direction.

A drilled hole will often have rough edges or burrs on

both surfaces. To remove these, select a drill bit twice

the size of the hole and hand rotate the point against the

burrs. When possible insert the drill bit in a file handle

when performing this job. Be careful not to ,burr the hole

too much. The hole should be a true cylinder and not

countersunk.

When the hole to be drilled is large, a pilot or guide hole

should be drilled first. This small hole will help guide the

larger drill and will also prevent the larger drill from

wandering across the metal.

REMOVING RIVETS

To remove a defective rivet or disassemble a unit joined

by rivets, use the following procedure:

1.

Select a twist drill equal in size or smaller than the

rivet shank.

2.

Drill into the exact center of the head to a depth

equal to the head thickness.

3.

Insert a pin punch in the hole and pry off the rivet

head.

4.

Drive the rivet shank out of the metal with a pin

punch.

DRILLING SAFETY PRACTICES

A misused drill can result in personal injury. When

performing a drilling operation, the following safety

precautions should be adhered to:

1.

Be sure that the drill selected is of the proper size,

free of rust, and that the flutes are clean.

2.

Keep the drill bit tight in the chuck.

3.

Be sure that the drill motor switch is off when

inserting the line cord into the receptacle.

4.

Never use a bent drill.

5.

Be certain that the cutting edges and point are not

dulled.

6.

Be sure that the metal stock is properly secured.

7. Always wear safety glasses.

8.

Turn off the drill motor before laying it down

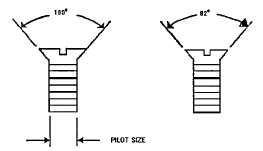

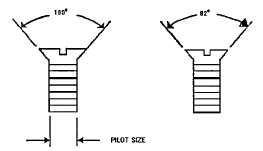

COUNTERSINKS

Countersinks are used to bevel the end of drilled holes

to fit countersink type screws and bolts. The countersink

stocked at the sites is equipped with a micrometer

adjustment (adjustable to .001 inch) and a stop pin that

prevents the countersink from cutting deeper than the

desired depth. The micrometer adjustment of this tool is

calibrated .

The countersink is designed to hold a variety of sizes of

cutting heads, both in 820 and 1000 point angles. The

reason for the two different joint angles is that, at a site,

screw and bolts are available with two different types of

countersunk heads. The countersunk cutting heads are

also designated according to the size of the hole being

countersunk, which is, in effect, the minor diameter of

the countersink cuter pilot. The purpose of the pilot is to

insure that the countersunk hole is concentric with the

screw hole.

Change 3 52-5.1