TM 9-243

USING THE PORTABLE ELECTRIC DRILL - CONTINUED

USING THE COUNTERSINK

The following is the procedure for using the

countersink:

1.

Always

wear

safety

glasses

when

using

countersinks

2.

Select the desired countersink cutter according to

point angle and pilot size.

3.

Attach countersink unit to a drill motor.

4.

Adjust the micrometer stop to the desired depth.

This will be slightly more than the thickness of the

head. Measurements for head thickness for most

screws available at the site are in the Coded Parts

List.

5.

Be sure the unit is secured properly to the drill chuck

before turning on the power.

6.

Hold the countersink guard in the left hand and the

drill motor In the right hand. Never turn on the

power without holding the countersink guard.

7.

When possible, countersink a test hole in scrap

stock to insure that the dimensions are correct.

8.

Countersink the hole approximately halfway, then

remove the tool and check the hole.

9.

Countersink the remainder of the hole until the guard

collar rests on the metal.

10. Examine the finished job to insure the hole is round

and even and that the screw fits properly.

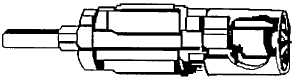

MICROMETER STOP COUNTERSINK

P/N 3204375 - Countersink Tool

P/N 3204386 - Complete Kit

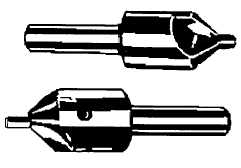

COUNTERSINK CUTTERS

Point Angle

Pilot Diameter

P/N 3204376

82

.098 in

P/N 3204377

82

.128 in

P/N 3204378

82

.159 in

P/N 3204379

82

3/16 in

P/N 3204380

82

1/4 in

P/N 3204381

100

.098 in

P/N 3204382

100

.128 in

P/N 3204383

100

.159 in

P/N 3204384

100

3/16 in

P/N 3204385

100

1/4 in

52-5.2/ (52-5.3 blank) Change 3