TM 9-4940-421-14

Table 3-2. Operator/Crew Preventive Maintenance Checks and Services (cont)

LOCATION

ITEM TO

NOT FULLY MISSION

PROCEDURE

INTERVAL

CHECK/SERVICE

CAPABLE IF:

ARC WELDING MACHINE

ENGINE

Air Cleaner Filter

Inspect for dirt and dust. Clean as

Filter is clogged with

Quarterly,

necessary (p. 3-3). If air cleaner filter

except more

dirt/dust.

is clogged with dirt/dust, notify orga-

frequently

nizational maintenance to replace it.

when operat-

ing under

dirty/dusty

conditions

weekly

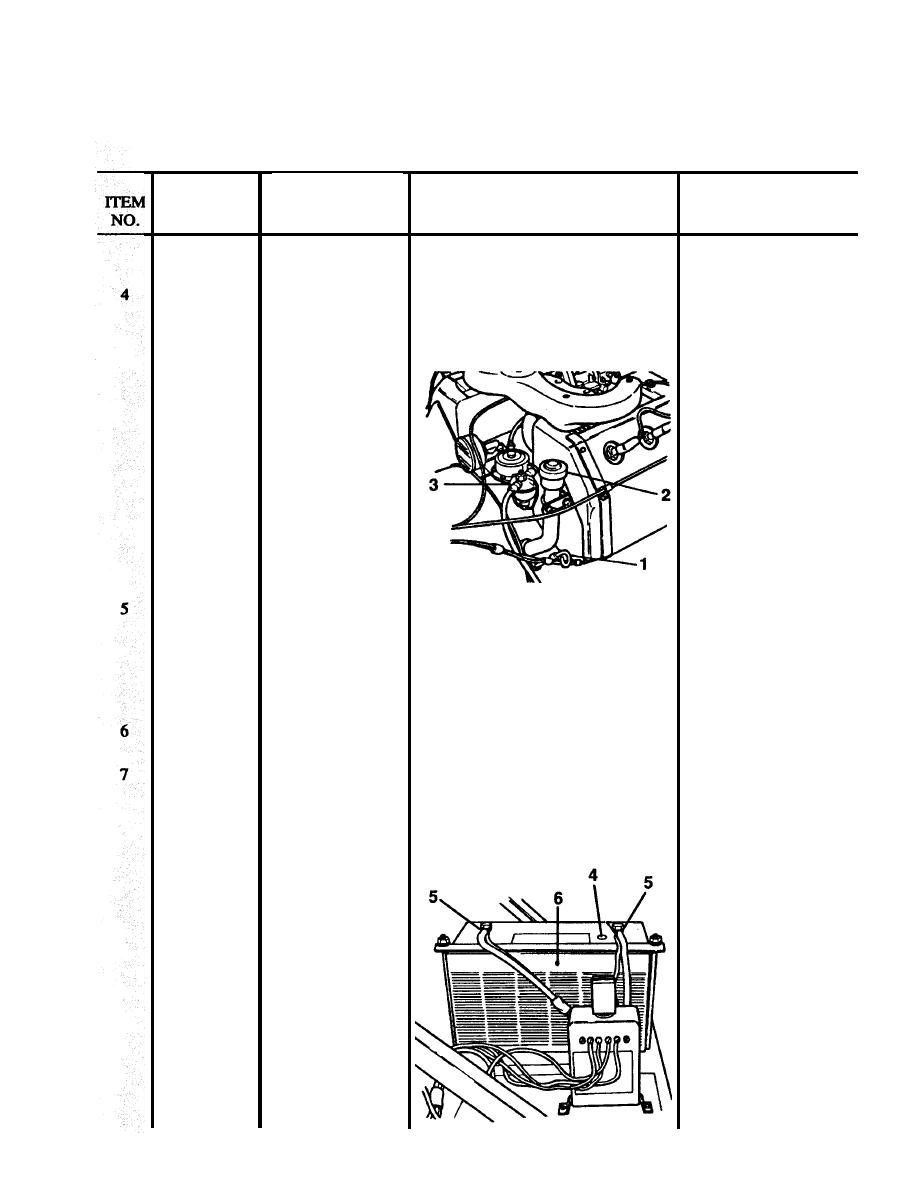

Engine Oil and

With shop parked on level ground,

Oil is 1 quart or more

Leaks

check dipstick (1) for level of engine

low or if class III oil

oil. Add oil thru filter (2) if oil is 1

leaks are present.

quart or more low. Report any class

III oil leaks to organizational mainte-

nance.

Monthly

Fuel Strainer

Check fuel strainer (3) for debris and

Fuel strainer is dirty.

clean as necessary (p. 3-5).

Air Cooling System

weekly

Inspect shrouds for looseness, missing

Air cooling system

Shrouds

components, and cracks. Tighten any

shrouds are loose,

loose fasteners. Notify organization~

cracked, or missing, or

maintenance of missing or cracked

if fasteners are missing.

shrouds or missing fasteners.

I

Change 1

3-2.1