TM 9-4940-421-14

Table 3-2. Operator/Crew Preventive Maintenancc Checks and Services (cont)

LOCATION

NOT FULLY MISSION

ITEM TO

ITEM

CAPABLE IF:

INTERVAL

CHECK/SERVICE

NO.

WARNING

Remove electrical power

from

air c o m p r e s s o r

(p. 2-2) before checking

or servicing. Failure to do

so could result in death or

injury to personnel.

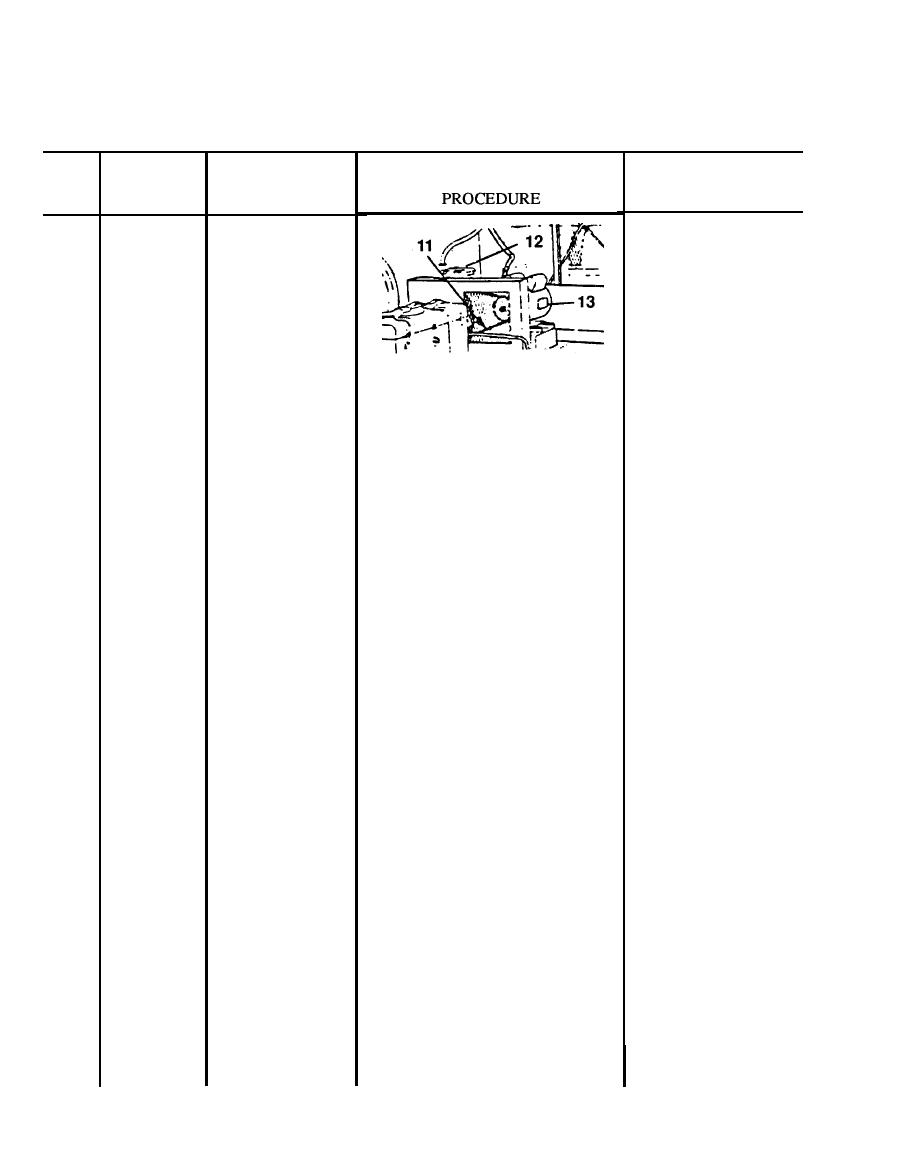

Vbelt is loose, broken,

Inspect Vbelt (11) for cracks, frays,

12

vbelt

Monthly

or defective.

and tears. Check tension for l/2-inch

(1.27 centimeter) deflection. If belt is

loose, broken, or defective, notify or-

ganizational maintenance.

Filter is torn, perforated,

Inspect air compressor inlet filter (12)

13

Air Compressor

Monthly, or

or clogged.

for dust/dirt. Clean if dirty (p. 3-3).

Inlet Filter

more fre-

Report any tears, perforation, or clog-

quently if op-

ging of the filter to organizational

erating in

maintenance.

sandy/dusty

environment

Check motor (13) for loose or missing Motor is not securely

Motor

Monthly

14

mounting hardware. Tighten any

mounted or any mount-

loose hardware. Notify organizational ing hardware is missing.

maintenance if any items of mounting

hardware are missing.

OVERALL SYSTEM CHECKOUT

WARNING

Injury or death can result if

shop set is not properly

grounded before opera-

tion.

Before starting engine check correc-

Shop set is not properly

15

Safety Ground

Before

tions between metal ground rod and

Operation

grounded when the wel-

wire lead to control panel assembly

dergenerator is placed

(p. 2-2 and 2-4).

in operation.

Change 1

3-2.4