TM 9-4940-421-14

Table 3-2. Operator/Crew preventive Maintenance Checks and Services (cont)

LOCATION

NOT FULLY MISSION

ITEM TO

ITEM

PROCEDURE

CAPABLE IF:

CHECK/SERVICE

INTERVAL

NO.

ARC WELDING MACHINE

ENGINE (CONT)

Battery cannot be

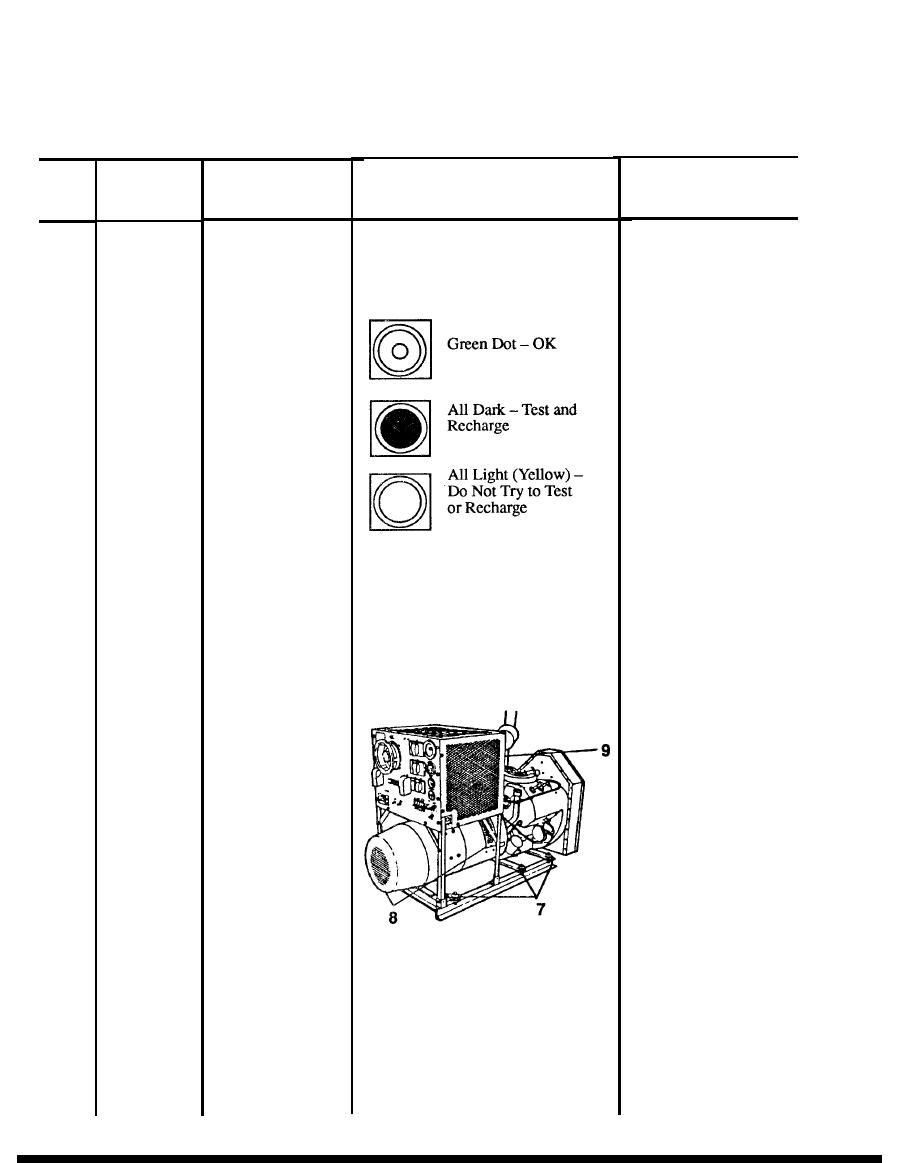

Check battery charge indicator (4) as

Battery

Monthly

8

follows:

charged or will not hold

a charge, or if connec-

tors are loose, or if con-

nectors and/or posts are

corroded, or if case is

cracked or leaking.

Inspect battery terminals and cable

connectors (5) for looseness and cor-

rosion. Tighten loose cable connec-

tors. Inspect case (6) for cracks and

leaks. Notify organizational mainte-

nance for battery servicing or replace-

ment.

ARC WELDING MACHINE

POWER UNIT

Mountings are loose or

Inspect both sides of unit for darnaged

Arc Welding Ma-

Weekly

9

damaged, or if prote-

or loose mountings (7). Tighten loose

chine Power Unit

mountings. Check for dirt or debris

ctive cage is not securely

obstructing vents (8). Clean off any

in place (3 or more

debris with a soft-bristle brush.

screws stripped or miss-

Check that protective cage (9) is se-

ing).

curely in place. Tighten screws if nec-

essary. Report any missing compo-

nents or damage to organizational

maintenance.

Change 1

3-2.2