TM 9-4940-421-14

REPAIR OF PNEUMATIC EQUIPMENT

Section I. I N T R O D U C T I O N

phase alternating current. The air compressor is a two

cylinder, single stage and rated at 5 cfm.

tions for the air compressor and drive motor. The motor

is rated at 1-1/2 horsepower, 115 volt, 60 hertz single

Section Il. A I R C O M P R E S S O R A N D R E L A T E D P A R T S

9-2. AIR COMPRESSOR.

(4) Inspect the crankcase for cracks, breaks,

a. Removal Refer to paragraph 4-36 for removal of

damaged threads, scoring, wearing, warpage and other

the air compressor.

defects.

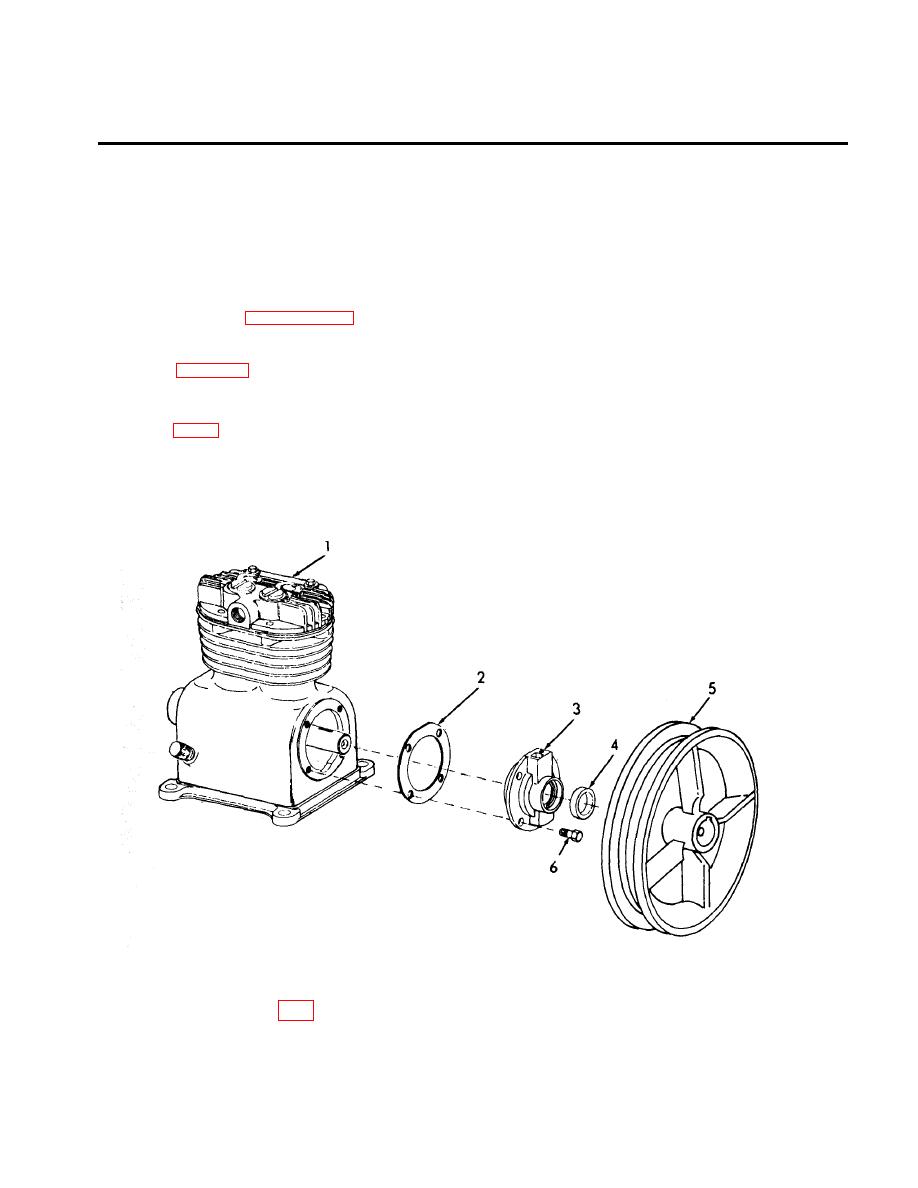

b. Disassembly. Disassemble air compressor as il-

d. Reassembly.

lustrated in figure 9-1.

(1) Reassemble the air compressor in reverse order

of removal.

c. Cleaning Inspection and Repair.

(2) Use the following torque values in reassem-

(1) Clean all parts with cleaning solvent and dry

bling the air compressor:

thoroughly (app D).

5 lbs. ft.

End cover bolts

(2) Inspect the cylinder head for cracks, breaks,

10 lbs. ft.

Pulley screw

warpage, and other damage.

e. Installation. Install the air compressor in reverse

(3) Inspect the baseplate for cracks, burrs and

order of removal,

other defects.

AR 701589

4. Oil seal

Legend for fig 9-1:

5. Pulley assembly

1. Air compressor

6. Bolt

2. End cover gasket

3. End cover