0010

TM 1-4920-924-13&P

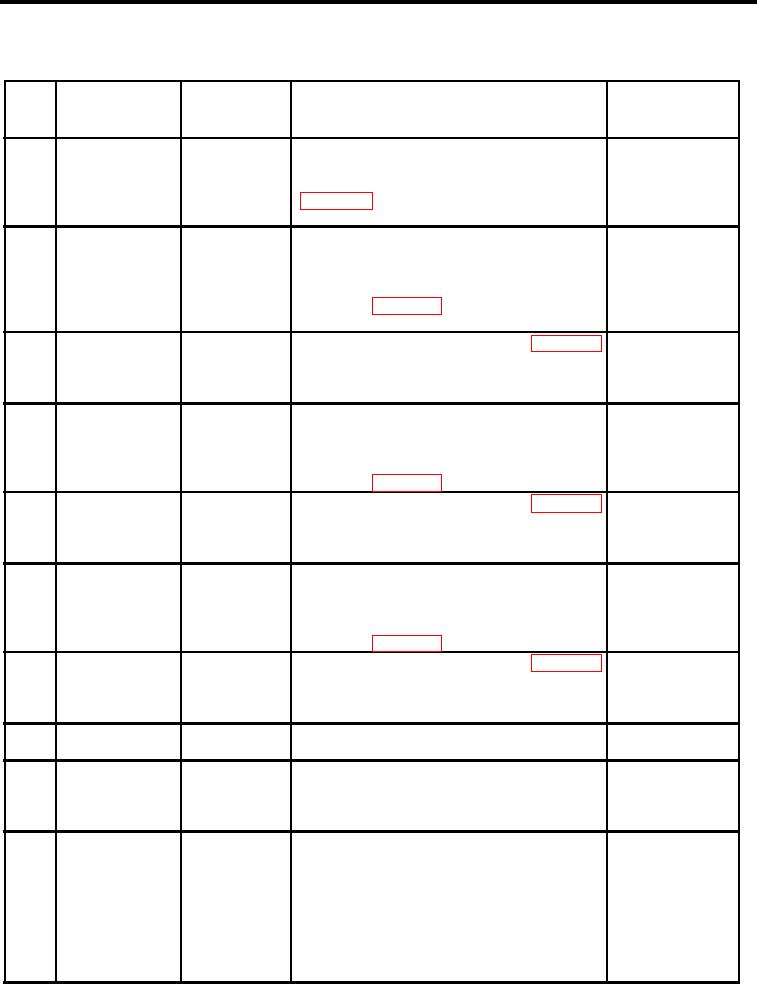

AVIATION SHOP EQUIPMENT CONTACT MAINTENANCE (AV SECM) SYSTEM PREVENTIVE MAINTENANCE

CHECKS AND SERVICES (PMCS) - (CONTINUED)

EQUIPMENT

ITEM TO BE

ITEM

INTERVAL

NOT READY/

CHECKED OR

NO.

PROCEDURE

AVAILABLE IF:

SERVICED

Roadside rack

26

Roadside Rack Check for proper operation of roadside rack

After

assembly s

Assembly

assembly drawer slides to ensure drawer

drawer slides

Drawer Slides

slide mechanisms lock and unlock properly

will not lock in the

stowed position.

27

Roadside Rack Ensure roadside rack assembly tie down

Tie down

After

Assembly

assemblies are not damaged due to dry rot or assemblies

Tie Down

broken fastener components. Ensure tie down cannot properly

Assemblies

assembly webbing material is not frayed, torn secure mission

essential

or broken (WP 0015).

equipment.

28

Roadside Rack Ensure all tool cases being stowed (WP 0002)

After

Assembly

on the roadside rack assembly are properly

Stowed Tool

secured to the roadside rack assembly using

Cases

tie down assemblies.

29

Curbside Rack Ensure curbside rack assembly tie down

Tie down

After

assemblies are not damaged due to dry rot or assembly cannot

Assembly

broken fastener components. Ensure tie down properly secure

Tie Down

assembly webbing material is not frayed, torn mission essential

Assemblies

or broken (WP 0015).

equipment.

30

Curbside Rack Ensure all tool cases being stowed (WP 0002)

After

on the curbside rack assembly are properly

Assembly

secured to the curbside rack assembly using

Stowed Tool

tie down assemblies.

Cases

Tie down

Ensure workbench assembly tie down

31

Workbench

After

assemblies are not damaged due to dry rot or assembly cannot

Assembly

broken fastener components. Ensure tie down properly secure

Tie Down

assembly webbing material is not frayed, torn mission essential

Assemblies

equipment.

or broken (WP 0015).

32

Workbench

Ensure all tool cases being stowed (WP 0002)

After

Assembly

on the workbench assembly are properly

Stowed Tool

secured to the workbench assembly using tie

Cases

down assemblies.

33

LED Flexible

After

Ensure LED lexible table lamp is operational.

Table Lamp

Power inverter is

34

Power Inverter Ensure power inverter is operational

After

nonoperational.

(Airpax Dimensions, Inc. DC to AC power

Inverters Owners Manual for Models: MIL-

24/6000H-3PHQ).

35

After

Oil-Free Air

Check oil-free air compressor for proper

Oil-free air

Compressor

operation (Instruction manual Oil-Free

compressor is

Portable Air Compressor).

nonoperational.

Ensure proper quick disconnect ittings are

Improper quick

installed on oil-free air compressor that are

disconnect ittings

compatible with equipment being used with

are installed

the AV SECM assembly.

on oil-free air

compressor.

00104