(2)

Type II (Oxygen) Section of Control Panel.

General Inspection instructions are as

follows

Inspect a part or parts of an oxygen

system in a clean contaminant free

environment.

(a)

Check for damaged gauges

(b)

Damaged cam lever or head valves

(c)

Damaged

or

cracked

hardware,

fittings, steel tubing and flex hoses

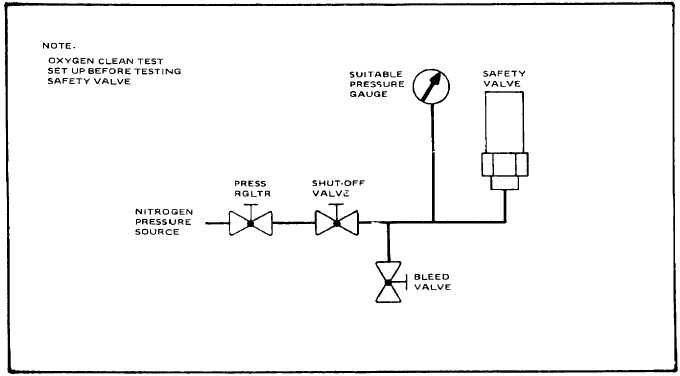

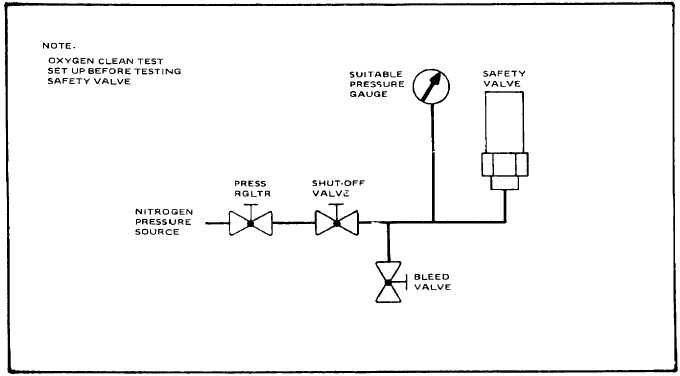

SAFETY VALVE TESTING system must be

oxygen clean

(3)

Test Safety Valves Connect oxygen safety

valve to be tested to an oxygen cleaned

gauge and regulated 3800 psig (26,182

kPa) clean nitrogen source (See Figure 6-4

)

Keep unprotected parts of body away

from valve opening during test

NOTE

Hydrostatic tester may be used in lieu of

nitrogen or air pressure source.

(a)

Starting

with

zero

pressure

increase

pressure to valve operating pressure

(b)

If safety valve relieves pressure prior to, or

after specified pressure and cannot be

reset, safety valve is defective

c.

Repair or Replacement Refer to paragraph 6-

3.c. for general repair or replacement procedures.

(1)

Replace damaged or defective nipples,

couplings and gauges.

(2)

Replace all threaded parts having worn,

stripped or damaged threads.

Figure 6-4. Typical Safety Valve Test Setup (Oxygen)

6-11