(3)

Valve seat (10) and bleed valve (11) for

nicks and burrs that will cause sticking or

clogging of orifices.

(4)

Spring (4) for breaks and set. Refer to

Table 6-1.

NOTE

Third stage spring (4) differs from the

first, second and accumulator bleed

valve springs (4). Keep separated.

d.

Repair or Replacement. Refer to paragraph 6-

3.c for general repair or replacement instructions.

(1)

Replace a damaged diaphragm.

(2)

Replace a defective spring.

e.

Assembly. To assemble the continuous bleed

valve subassembly, proceed as follows:

NOTE

Repair kits consisting of spring (4),

diaphragm plate (6). diaphragm (7),

orifice screw (8), valve plunger (9), valve

seat (10), and bleed valve (11) are

available for each of the two bleed valve

subassemblies. The kits differ only in

springs (4). Care shall be taken so as

not to assemble the wrong spring. At

overhaul of the bleed valve

subassemblies, these kits shall be used.

(1)

Assemble orifice screw (8), diaphragm (7),

diaphragm plate (6), and secure together

with locknut (5).

(2)

Install bleed valve (11) in bore of valve

seat (10) with tapered end of valve (11)

into bore first. Screw valve seat (10) into

body until head of seat bottoms in body.

Tighten securely.

(3)

Place valve plunger (9) in center hole of

valve seat head (10) making certain small

end of plunger (9) enters the small air

passage hole in seat (10).

(4)

Position diaphragm (7) aligning diaphragm

holes with tapped holes in body (12).

When assembling spring (4), make

certain that proper spring is assembled

for the third stage application. The third

stage spring has free length of 2-3/4

inches, whereas, first and second stage

spring free length is 2 inches. Assemble

the third stage spring in the assembly

that has a 3 stamped into the face of

body (12).

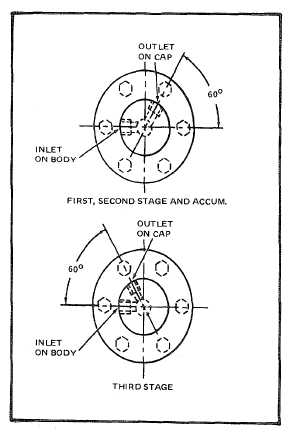

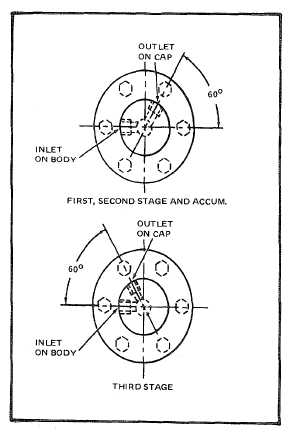

(5)

Assemble proper spring (4) on diaphragm

plate (6). Assemble cap (1) to body (12),

aligning holes so that correct inlet to outlet

relationship is obtained. (See Figure 6-9).

Attach cap to body with lock washers (3)

and cap screws (2). Tighten cap screws

(2) to 16 + 1 pound-inch (1.81 + 0.113

Nm) of torque.

6-30.

Drain Valve Assembly (See Figure 8-27). The

following paragraphs contain disassembly, cleaning,

inspection, repair or replacement and assembly

instructions for the drain valve assembly.

Figure 6-9. Bleed Valve Port Locations

6-36