TM 9-4940-421-14

(5) Inspect breaker points for roughness, burning

the distributor in reverse order of disassembly.

and pitting. Replace damaged points.

(6) Inspect the coil to distributor primary wire for

the distributor. Be sure to lubricate the cam and wick.

broken, bare, or frayed wire. Replace a damaged wire.

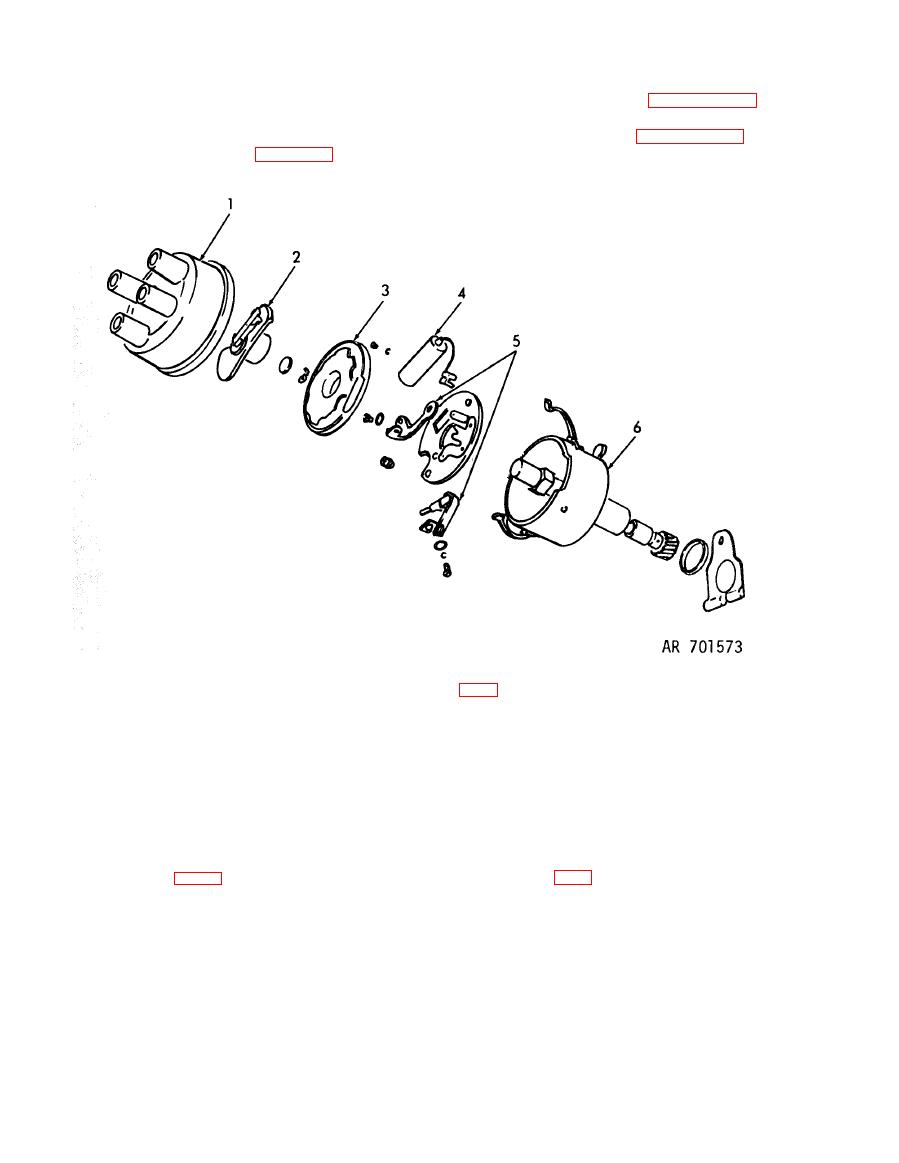

Legend for fig 6-2:

1. Distributor cap

2. Rotor

3. Dust cover

4, Condensor

5. Points Set

6. Base Assembly

.

Section III. E N G I N E D I S A S S E M B L Y

6-8. FYLWHEEL.

(1) Wash all parts in cleaning solvent and dry

a. Removal (fig 6-3).

thoroughly (app D). Use a wire brush to clean rust and

.

(1) Drive the crank pin out of the crankshaft.

scale from the flywheel. Be careful and not damage the

Remove the nut and lockwasher.

flywheel alternator rotor.

(2) Hit the end of the crankshaft with a soft ham-

(2) Inspect the flywheel for cracks or broken

mer to loosen the flywheel. If the flywheel is not

vanes. Inspect the flywheel ring gear for broken or

loosened after two or three blows, use a puller to

cracked teeth. Replace a damaged flywheel.

remove it.

c. Installation. Install flywheel in reverse order of

(3) Remove the key from the crankshaft.

removal.

b. Cleaning and Inspection.