TM 9-4940-421-14

b. Cleaning and Inspection.

(2) Examine the pump body and gear for cracks or

(1) Wash all of the parts in cleaning solvent and

breaks and replace a defective oil pump.

dry thoroughly. Use a fiber brush to clean the screen

AR 701582

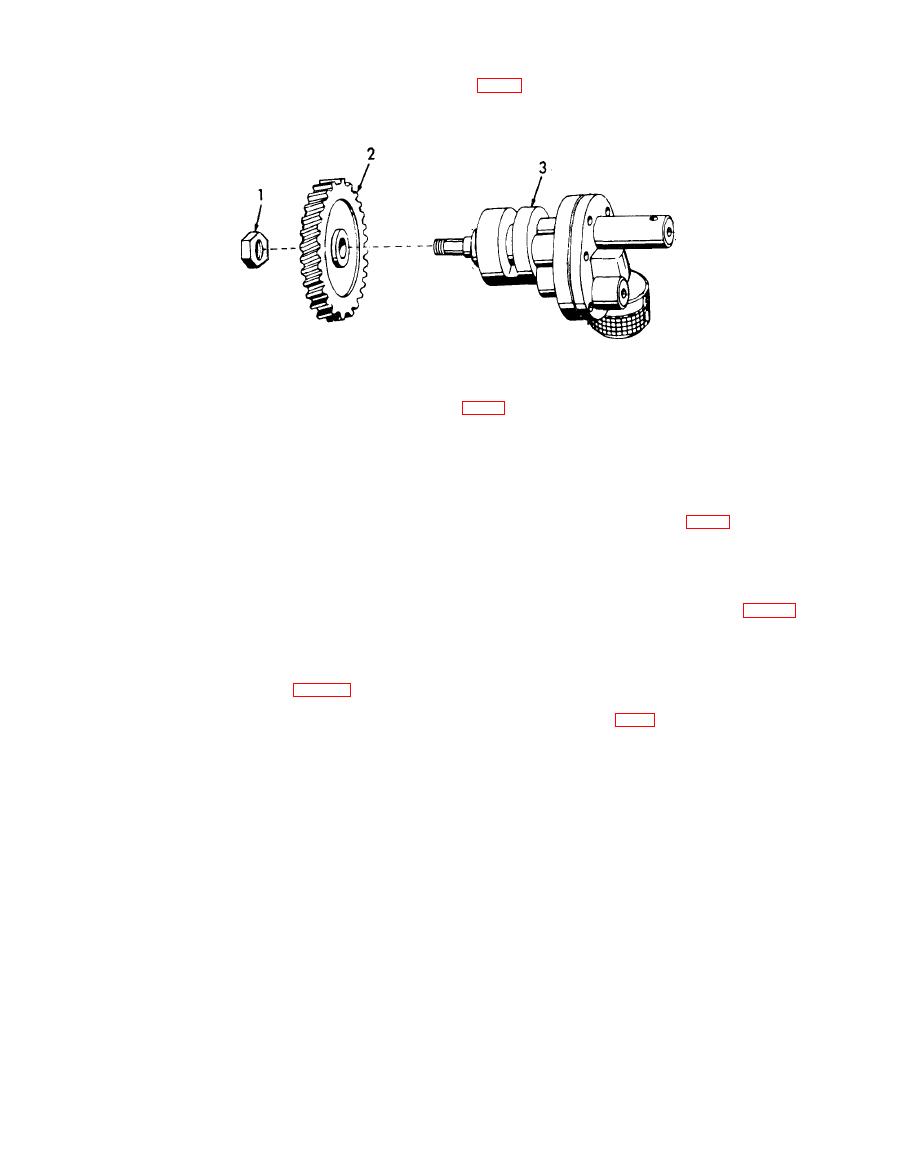

Legend for fig 6-11:

1. Nut

2. Gear

3. Body

b. Removal.

c. Installation.

(1) Remove the gear cover (fig 6-9).

(1) Install the oil pump in the crankcase with the

(2) Remove the setscrew from the left-hand side of

screen facing toward the bottom of the engine. Secure

the crankcase which locks the idler shaft in position.

with the setscrew and pipe plug.

(3) Using a gear puller remove the idler shaft and

(2) Install the woodruff key in the oil pump shaft.

idler gear assembly.

(3) Install the gear (2) and secure with the nut (l).

(4) Remove the three capscrews (1, fig 6-13) and

(4) Apply a thin coat of grease to a new cover

lockwashers (2) that secure the camshaft gear (3) to the

plate gasket and position the gear cover on the

camshaft. Pull the camshaft thrust plunger (7) from

crankcase and secure with capscrews and lockwashers.

the end of the camshaft. Remove the plunger spring (6).

Tighten to 6-9 lbs. ft.

c. Cleaning and Inspection.

(1) Wash the removed gears with cleaning solvent

a. General. The timing-gear train is located at the

and dry thoroughly (app D).

same end of the engine as the flywheel, and is enclosed

(2) Examine the gears for broken, cracked or chip-

in a gear cover. It comprises the governor gear,

ped teeth. Replace any damaged or excessively worn

camshaft gear, crankshaft gear, idler gear and oil

gears.

pump gear. The governor gear can be removed from the

(3) Inspect the idler gear shaft for scoring or pit-

gear train without removing the gear cover. The re-

ting. Remove any roughness with a fine grade of emery

maining gears, with the exception of the crankshaft

cloth.

gear, can be removed after the gear cover is removed.