Section VI. TROUBLESHOOTING

4-10. General

probable causes of the trouble. The corrective

This section provides information u s e f u l in

a c t i o n recommended is described opposite the

diagnosing and correcting unsatisfactory operation

probable cause.

or failure of the shop set and its components.

Malfunctions which may occur are listed in table 4-

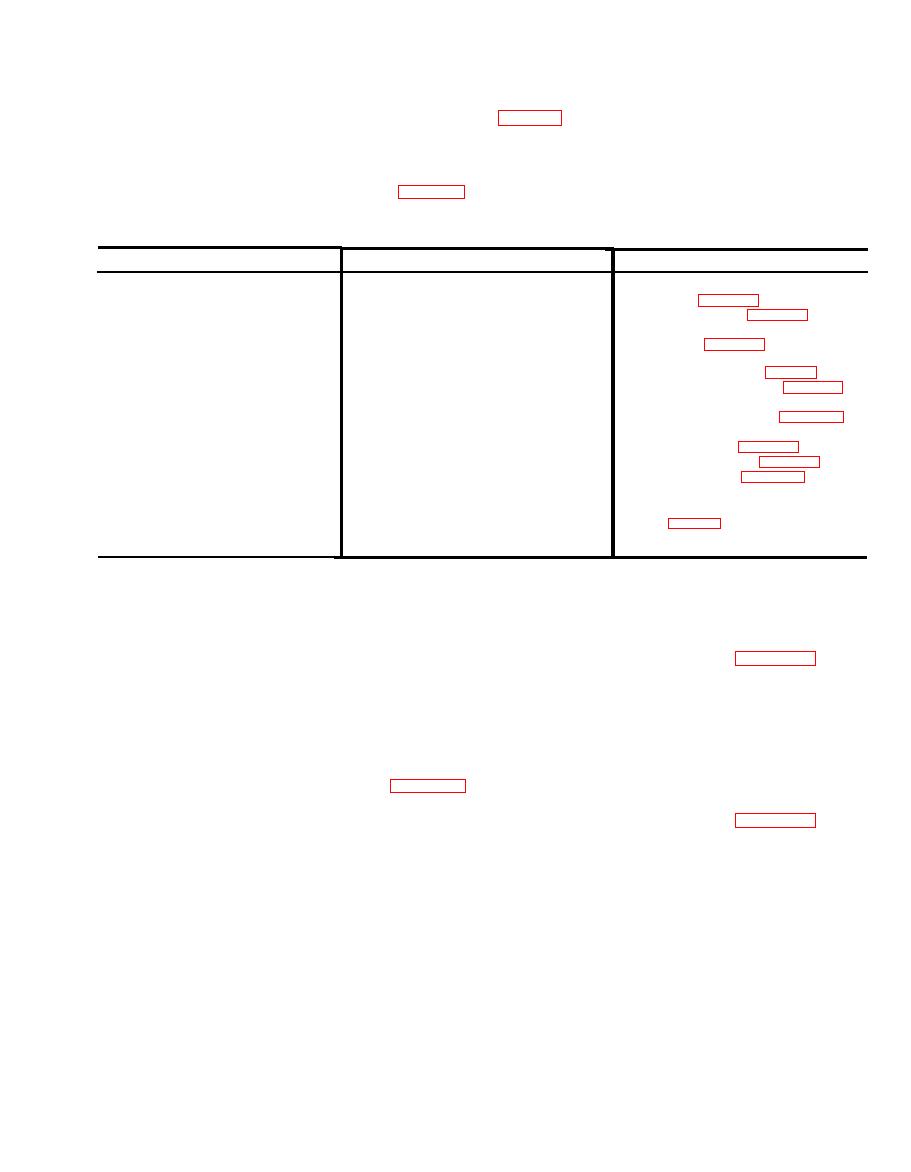

Table 4-2. Troubleshooting

Malfunction

Corrective Action

Probable Cause

a. Place power selector switch to

1.

Dynamotor-welder will not start

a. Power selector switch in OFF

when internal power is used.

position

GEN (para 2-13a).

b. Increase RPM (para 2-13a).

b. RPM too low.

Interchange any two incoming power

E x t e r n a l power lines connected

2.

Dynamotor-welder

rotates

in

wrong.

wrong direction when external

leads. (para 2-13 b).

power is used.

a. Clean air cleaner (para 3-8).

a. Air cleaner clogged.

3. Air compressor air pressure low.

b. Adjust or replace switch (para

h. Electric pressure switch defective

4-32).

or out of adjustment.

Adjust or replace switch (para 4-32).

Electric pressure switch defective or

4. Air compressor air pressure too

out of adjustment.

high.

a. Bleed system (para 4-26).

5. Side lifting hydraulic system does

a. Air in hydraulic system.

b. Replace cylinder (para 4-27).

b. Side lifting cylinder defective.

not operate properly.

c. Replace pump (para 4-26).

c. Side lifting hydraulic pump

defective.

6. Sides lower too quickly or too

Adjust or replace flow control valve

Side lifting hydraulic pump flow

slowly.

c o n t r o l v a l v e n o t adjusted

properly or defective.

Section VII. MAINTENANCE OF ELECTRICAL SYSTEMS

4-11. General

a. Removal. Remove the service and blackout

clearance lights as illustrated in figure 4-1.

The shop set contains three electrical systems: A

b. Cleaning and Inspection.

24-volt D. C. system, an alternating current system,

(1) Clean all parts with approved cleaning

both 120- and 240- volts, and a D.C. welding

solvent and dry thoroughly.

system. The 24-volt system, powered by the bat-

(2) Inspect all parts for damaged threads,

teries, is comprised of the driving lights and the.

bends, cracks, breaks and other damage. Inspect

internal emergency lights. The alternating current

for a defective lamp and any corrosion. Replace any

system includes all shop set lights, switches, and

defective parts.

receptacles for 120- and 240-volts. Refer to figures

c. Installation. Install the service and blackout

1-4, 1-5, and 1-6, for the wiring diagrams.

clearance lights as illustrated in figure 4-1.