Note. Use a spring scale to check brush spring

tension. Correct tension is 32 ounces.

(2) Install end wrappers (par. 77).

a. General. Loss of residual magnetism in the

exciter field frame can be caused by long periods of

idleness, a short circuit, or a sudden surge of current

from an outside power source. Loss of magnetism .

will cause the generator-welder to fail to build up

voltage in any of its components. To magnetize the

exciter field frame follow the instructions in b below.

b. Magnetizing Exciter Field.

(1) Remove the end wrappers (par. 77).

(2) Raise the exciter brushes from the com-

mutator (par. 79).

(3) Using an outside source of direct current

(a storage battery is satisfactory), apply

the current to two adjacent exciter brushes

for a few seconds and remove the current

source.

(4) Lower the exciter brushes to the commuta-

tor (par. 79).

(5) Install the end wrapper (par. 77).

(6) Start the generator-welder (pars. 16 and

17).

(7) Place the welding polarity control switch

in the STRAIGHT position (par. 16).

(8) If the exciter fields are properly magnetized,

and adjustment.

the direct current voltmeter will indicate

voltage on the right side of the scale,

c. Brush Seating. Refer to TM 5-764.

(9) If the direct current voltmcter indicates

Note. To avoid wastage of brush material, sand only until

voltagc on the left sick of the scale, stop the

radius of commutator is obtained. Blow out carbon dust with

generator-welder (pars. 18 and 19) and

low-pressure, dry, compressed air.

repeat steps (1) and (2) above.

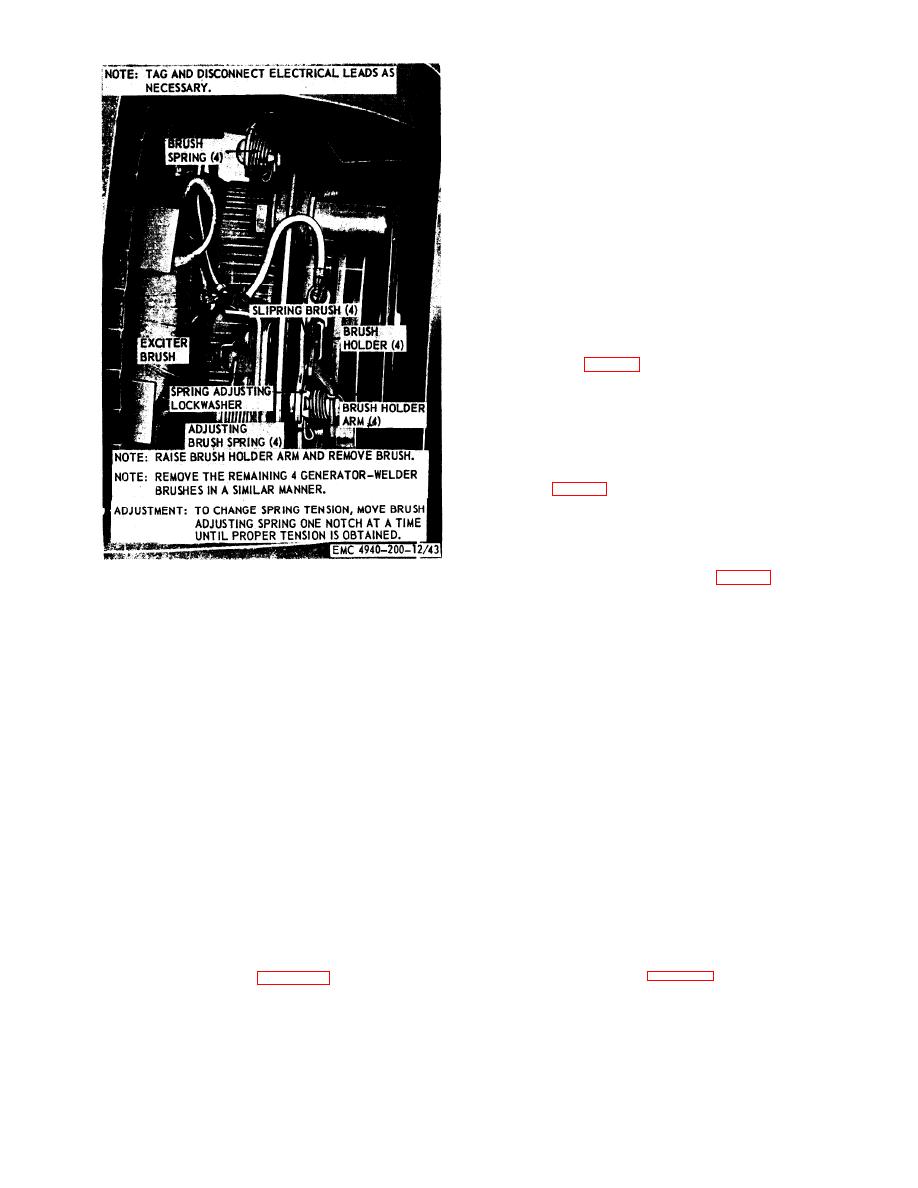

d. Installation.

(lo) Repeat steps (4) through (8) above and

(1) Refer to figure 55 and install the generator-

stop the generator-welder (pars. 18 and 19).

welder brushes to the generator-welder.

Section Xl. AIR COMPRESSOR

b. Cleaning and Inspection.

81. General

(1) Clean the handle with an approved clean-

The air compressor (Model SECM shop set) is a

ing solvent and dry thoroughly.

portable, diaphragm-type (Compressor with a direct

(2) Inspect the handle for dents, cracks, breaks,

drive to a 110-volt, split-phase motor. Mounted

or other damage. Replace a damaged

above the motor is the compressor head equipped

with a carrying handle. This model is designed to

handle.

start under normal or light loads.

Inspect the mounting hardware for worn

(3)

Replace as required.

or damaged threads.

82. Handle

handle to the compressor head.

compressor handle from the compressor head.

TAGO 5672-A