85. Compressor Housing and Compressor

Motor

a. Removal.

(1) Remove base plates and rubber mounts

(par. 83).

(2) Remove compressor head (par. 84).

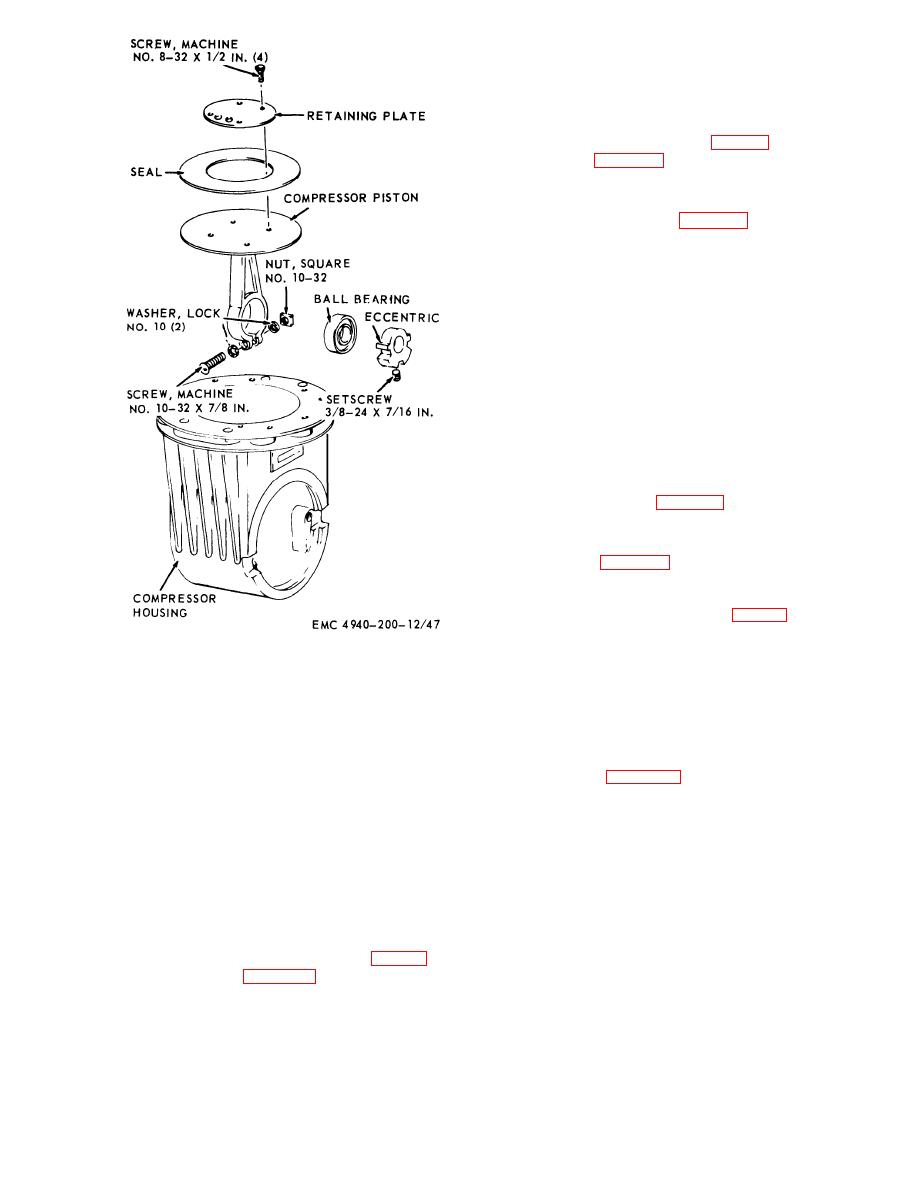

(3) Refer to figure 58 and remove the bearing

cover, bearing, and compressor housing

from the compressor mot or.

semble the compressor housing.

c. Cleaning, Inspection, and Repair.

(1) Clean all metal parts with an approved

cleaning solvent and dry thoroughly.

(2) Inspect the housing for cracks, breaks, or

other damage. Replace a damaged housing,

(3) Inspect the bearings, piston, and eccentric

f o r scoring, nicks j and wear. Replace

damaged bearings, piston, or eccentric.

(4) Inspect all hardware for worn or damaged

threads. Replace as necessary.

(5) Connect motor to outside power source and

inspect for proper operation. Replace a

defective motor.

d. Reassembly. Refer to figure 59 and reassemble

the compressor housing in reverse order.

c. Installation.

(1) Refer to figure 58 and install the bearing,

bearing cover , and compressor housing to

the compressor motor.

(3) Install the rubber mounts and base plates

(par. 83).

homing, disassembly and reassembly.

Compressor

Section X11. SHOP SET BODY

extinguisher b r a c k e t f r o m t h e M o d e l

86. General

SECM shop set body.

The shop set body is a riveted structure contain-

(3) Refer to figure 60 and remove the fire

ing eight watertight compartments and is mounted

extinguisher bracket in a like manner from

on a modified 4 by 4 truck chassis. The shop set

the floorboard of the cab on Model CMU-5

body includes tool clips, safety and mounting straps,

shop set.

doors, lock and latch assemblies, brackets and

b. Cleaning and Inspection.

braces, tailgate and fasteners, oxygen cylinder rack,

(1) Clean all parts with an approved cleaning

and electrical receptacles.

solvent and dry thoroughly.

(2) Inspect the fire extinguisher bracket for

87. Fire Extinguisher Bracket

dents, cracks, or breaks. Straighten all

a. Removal.

dents and replace a defective bracket.

(3) Inspect the hardware for worn or damaged

(1) Remove the fire extinguisher (par. 27).

threads. Replace as necessary.

(2) Refer to figure 60 and remove the fire

TACO 5672-A